Quality

Ovation has a set of processes to make sure the highest manufacturing standards are applied to every products you order. We inspect each order dimensionally and visually, both during and after production, so that your custom components are delivered on time and to your exact specifications.

Strict quality control management

With comprehensive equipment and processes such as supplier assessment, raw material inspection, production SOP control, aging testing, shipping testing. Our lighting products are delivered to clients with high quality and bring you value and benefit.

Supplier assessment

We have a comprehensive precess for selecting material supplier. Only work with suppliers with good reputation and reliable quality.

In-comming inspection

Also called pre-production inspection. Product materials require check for quality as they come in from vendors.

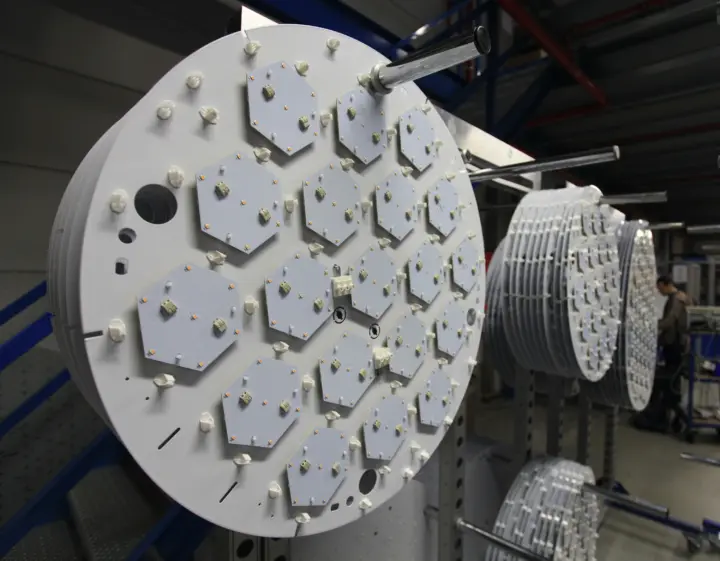

In-process inspection

Also called During Production Inspection. Goods are 100% inspected in production line. The idea is to monitor and find quality issues before they occur and avoid reworking.

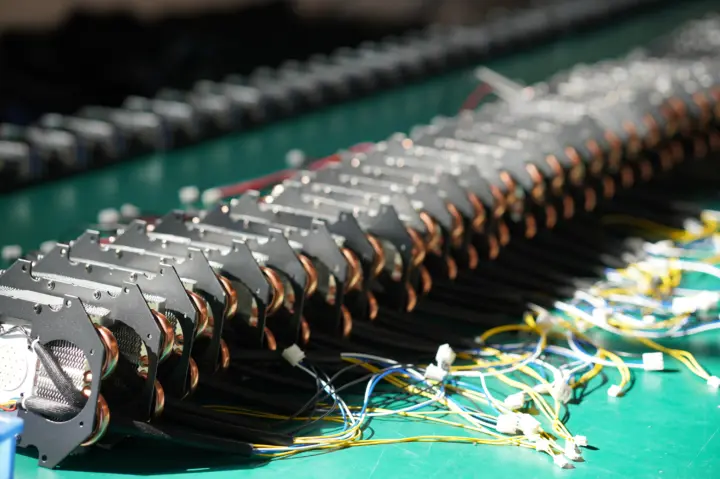

Aging testing

Every single product dlivered to clients will be 100% tested for at least 8 hours before packing.

Final inspection

QC conducts measurements of the finished products to ensure they were produced according to specifications.

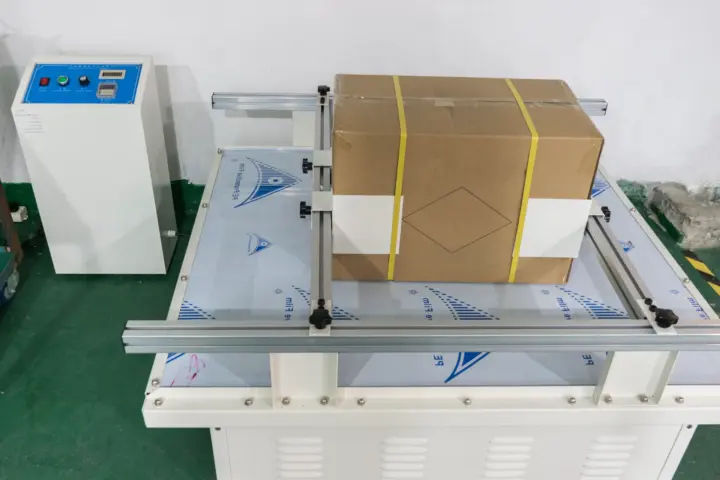

Shipment testing

We will pick several items to do vibration test to simulate the real transportation environment.

Quality documentation

We track the performance of our suppliers to ensure that orders meet our Standard. Here is some certificate regarding our factory and products. Certifications and reports can be provided upon request.

3rd Award – China International Lighting Design

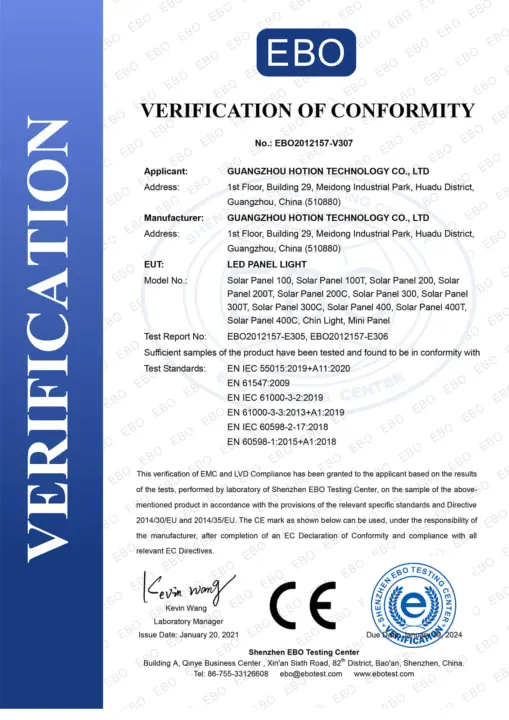

AwardsCE certificate – LED Panels

CECE certificate – LED Profiles

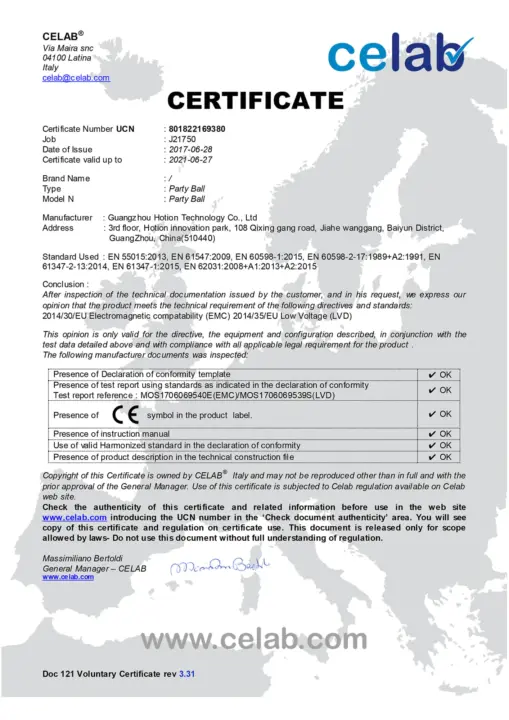

CECE certificate – Party Ball

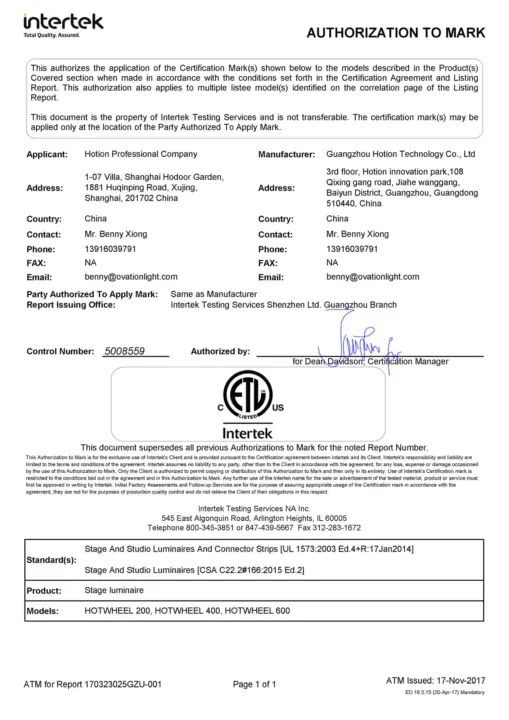

CEETL certificate – Hotwheel series

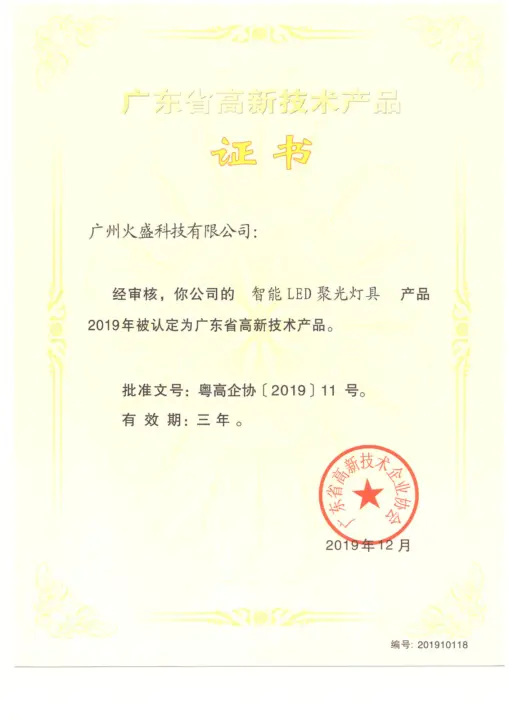

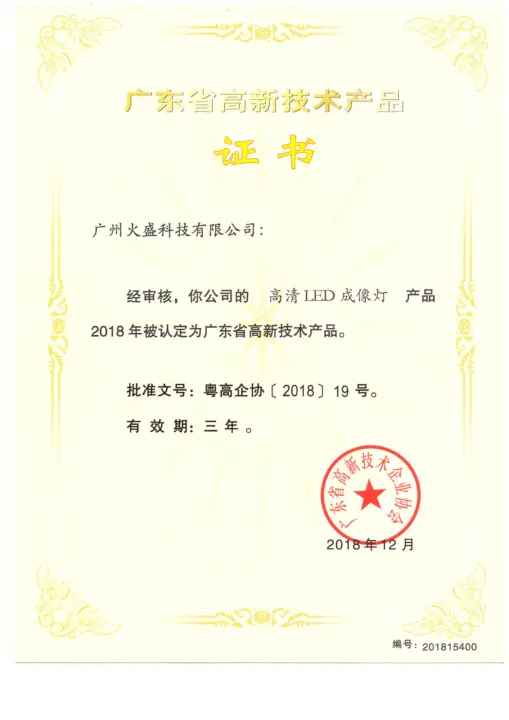

ETLHigh tech product – Fresnels

High-tech productHigh tech product – Profiles

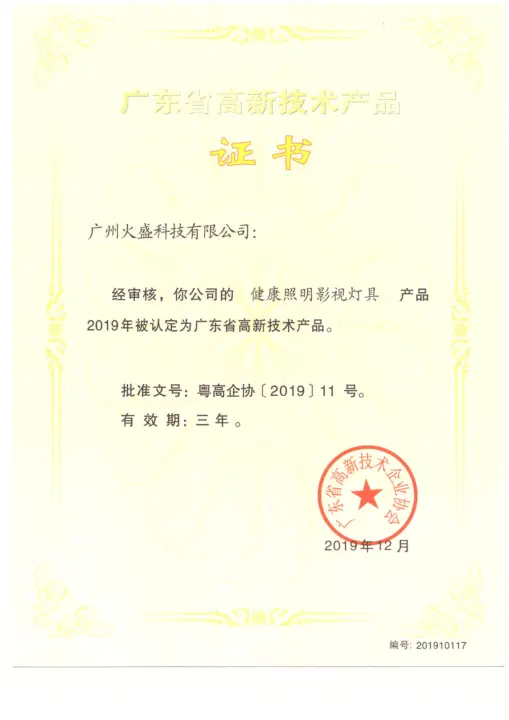

High-tech productHigh tech product – Studio lights

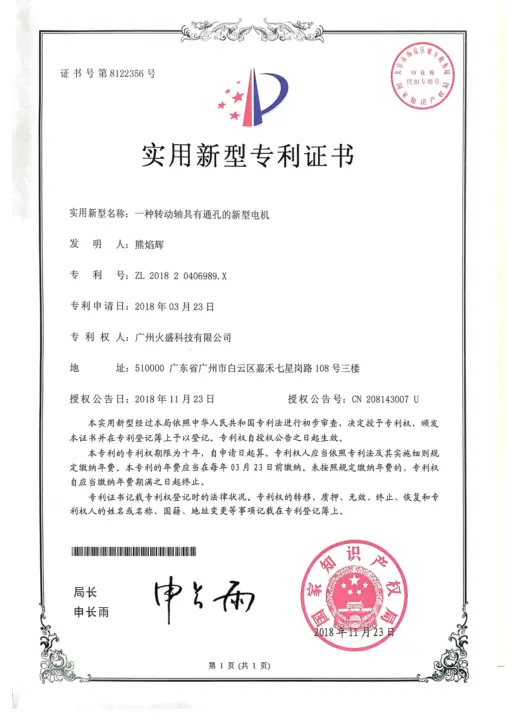

High-tech productPatent – Moto

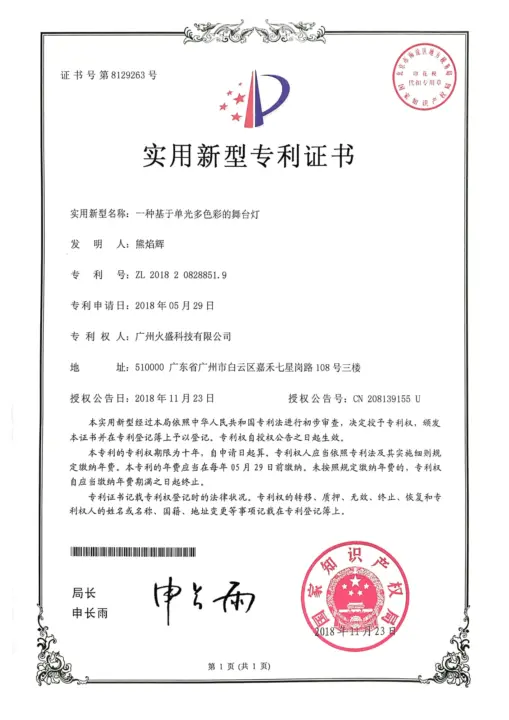

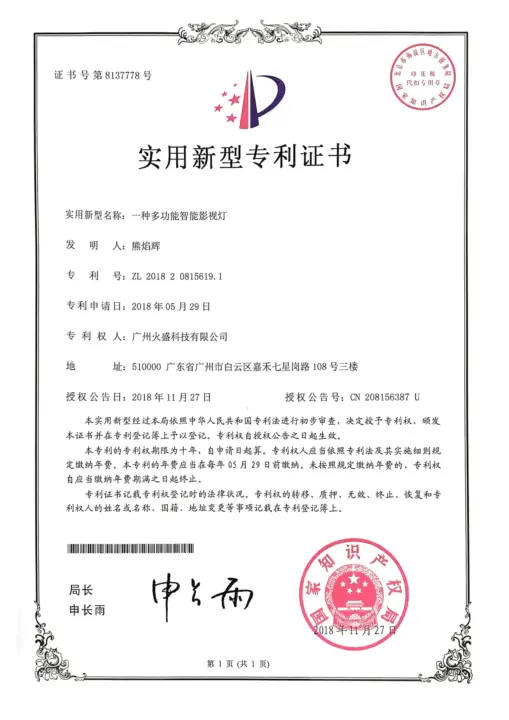

PatentPatent – stage light

PatentPatent – studio light

PatentRED certificate – Party Ball

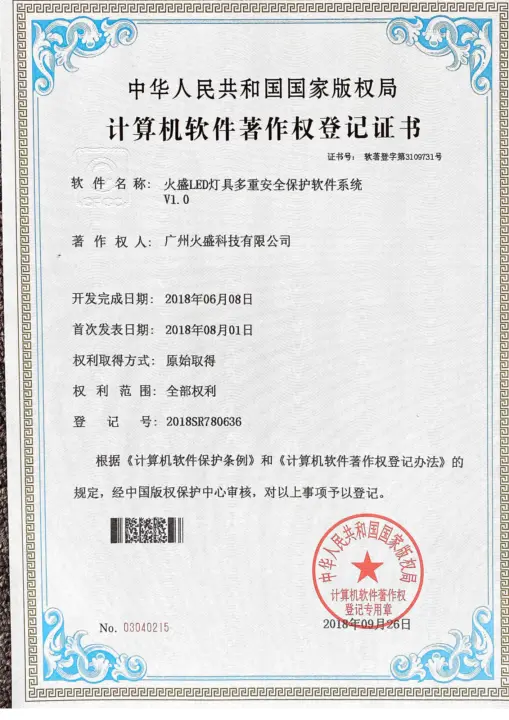

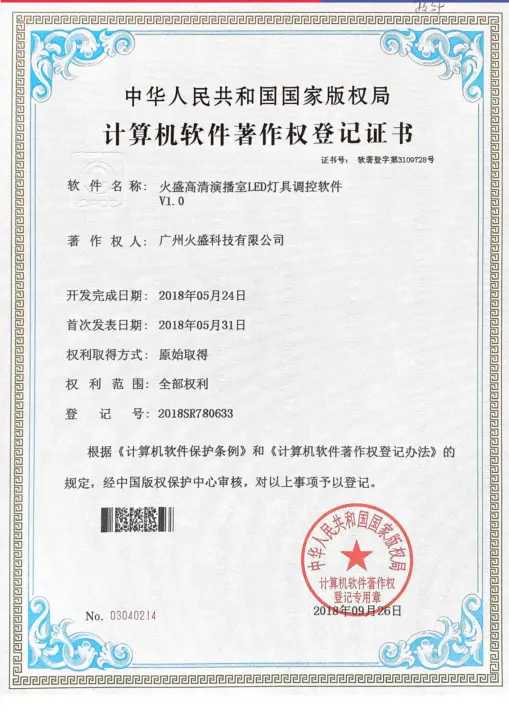

REDSoftware patent – 1

PatentSoftware patent – 2

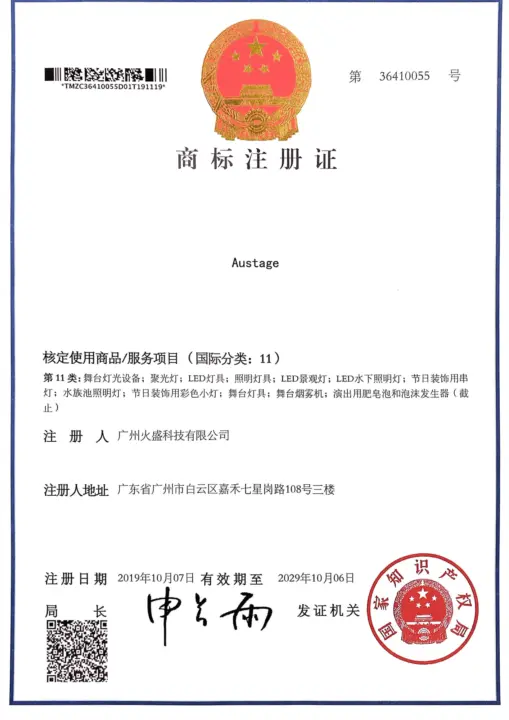

PatentTrademark – Austage

TrademarkTrademark – Ustage

Trademark